Product Description

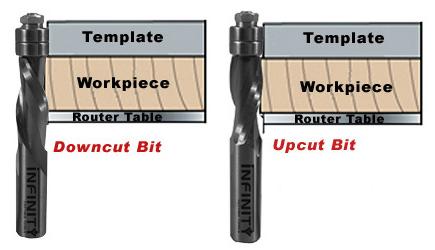

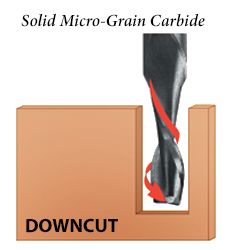

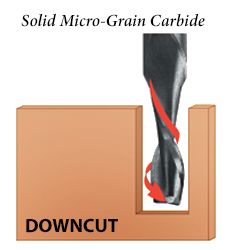

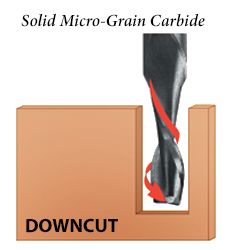

Downcut spiral bits can be used for cutting grooves, dadoes and inlays. Downcut bits don't clear chips as quickly as upcut spiral bits but their downcut geometry pushes wood fibres down into the cut, leaving a cleaner top surface on your workpiece with minimal tearout. Downcut bits do require a slower feed rate and a lighter depth of cut is preferable.

One important thing to take note of is that if you do use the spiral router bits on a router table, then the downcut bit will actually push material towards your workpiece, sometimes raising the workpiece off the table. It will still make a clean edged cut, but it is important to use a good downward feather board system to prevent the workpiece lifting. Take light passes when using it on a router table.

If you need both top and bottom surfaces to be cut cleanly, use our up and down spiral bits

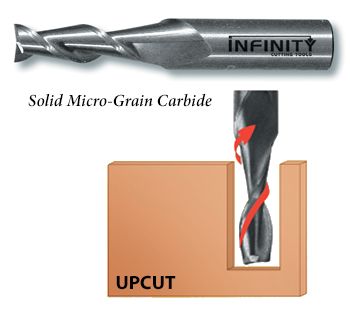

Infinity solid carbide spiral bits feature a helical design that is continuously in contact with the workpiece. This constant shearing action produces smoother, cleaner cuts than a straight router bit which repeatedly smacks the cutting edge against the wood. A spiral bit's geometry and top point also allow you to plunge it into your work like a drill.

Our solid carbide spiral router bits are designed to provide remarkable performance and durability. They quickly slice through hard or soft wood, plywood and composites such as MDF or particle board. Manufactured using state-of-the-art computer controlled machinery, these micro-grain carbide cutters feature our optimal helix design and a strong body that reduces vibration and lasts up to 300% longer than regular router bits.

Please note: The recommended depth of cut for any single pass is half of the diameter of the tool. For example, if you are using a ¼″ diameter cutter you should only take a ⅛″ depth of cut for any single pass.